What are the requirements for the inspection time of the jaw crusher?

Time:2019-07-29 Back to list

If you are looking for related products or have any other questions, please feel free to call our sales hotline or click the right button to ask for a quote online!

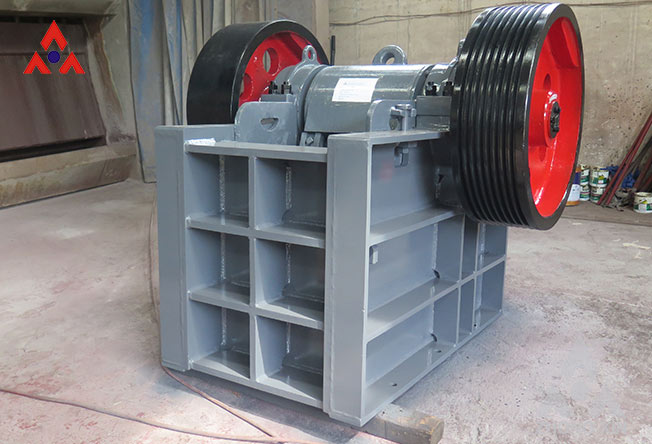

The jaw crusher requires periodic maintenance to detect potential safety hazards in a timely manner. This is of * help to the production of the jaw crusher in the later stage. What is the maintenance cycle?

First, the monthly repair, the main content of the repair is the bearing lubrication of the broken machine, although we usually check the situation when using the machine, but the focus is different, the inspection is more in the month of repair The *, including the condition of the oil pipe and the wear of the bearing, as well as the cleaning of the lubricating device of the jaw crusher, can achieve better lubrication effect.

The second is the season repair. The content of the season repair includes the contents of the monthly repair. In addition, the replacement of the large and small gears should be included. Because after one quarter of work, the wear of these two components will be more serious, and the smooth operation of the smashing machine can no long be assisted. It will have an impact on the efficiency of production and so on, so it needs to be replaced.

The third is the annual repair, which includes the contents of the season repair, and then includes the inspection of all the parts. If the parts with more serious wear are found, they need to be replaced, and the repairs can be repaired without serious wear. Then, look at the technology of the smashing machine. Whether the * needs to be updated or not, it should be carried out in time if necessary.

The second is the season repair. The content of the season repair includes the contents of the monthly repair. In addition, the replacement of the large and small gears should be included. Because after one quarter of work, the wear of these two components will be more serious, and the smooth operation of the smashing machine can no long be assisted. It will have an impact on the efficiency of production and so on, so it needs to be replaced.

The third is the annual repair, which includes the contents of the season repair, and then includes the inspection of all the parts. If the parts with more serious wear are found, they need to be replaced, and the repairs can be repaired without serious wear. Then, look at the technology of the smashing machine. Whether the * needs to be updated or not, it should be carried out in time if necessary.

Related News

- Performance advantages of impact crusher

- Sand making machine occupies an important position in the equipment of the mining industry

- What aspects should be paid special attention to in a single-cylinder cone mobile crushing station?

- 7 ways to improve the efficiency of sand washing machines

- How to improve the sand output rate of sand making machine?

- Installation points of the five major components of the gyratory crusher

Leave message

Product Center

- Cone Crusher Machine

- • PXH series gyratory crusher

- • Single cylinder cone crusher

- • Spring Cone Crusher

- • Compound Cone Crusher

- • PSG Series Compound Cone Crusher

- Stone Crushing Machine

- • Sand Making Machine

- • Jaw Crusher

- • Vertical Shaft Impact Crusher

- • Impact Crusher

- Screening Sand Washing

- • XS Sand washing machine

- • circular Vibrating Screen

- • ZSW Series Vibrating Feeder

Materials

- • River Stone Crushing Processing

- • Iron Ore Crushing Processing

- • Aggregate Crushing Processing

- • Granite Crushing Processing

- • Basalt Crushing Processing

- • Gold Ore Crushing Processing

Contact Us

Add:Room 609,Easttower,xiyuan international square,Jianshe Road,Zhengzhou City,Henan Province,China

Tel:+86-371-67660555

Whatsapp:+0086-13676922906

Email:sales@zxcrusher.com

Web:www.zxstonecrusher.com

Chat Online

Chat Online